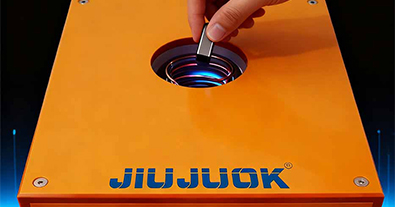

JiuJu Magnetizing Equipment: High Frequency Magnetic Field Generator Upgraded, 0.1 Seconds for Efficient Magnetization

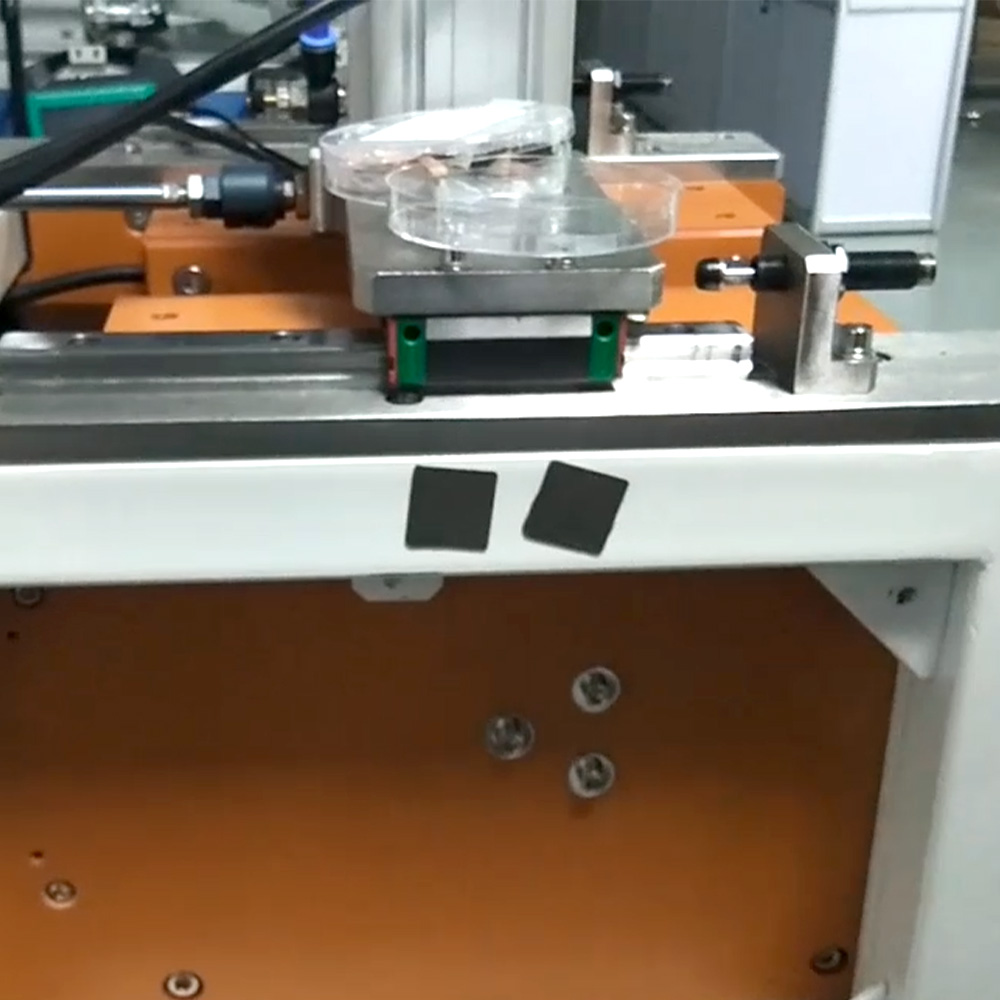

End-to-End Solution for Magnetization Automation

Automated Magnetic Charging Integrated Solution

In industrial production and equipment manufacturing scenarios, the performance of motors has a direct impact on the efficiency and service life of products. Poor energy efficiency, fluctuating operation and high energy consumption of motors are mostly related to the technical control of the magnetization process. Industry data shows that the magnetization process is not up to standard, which can easily lead to motor performance does not meet the application requirements, which will increase the average production cost of the enterprise 12%-15%, equipment failure rate 20%. If you want to properly deal with these problems, the selection of professional and reliable magnetization equipment is particularly critical. Relying on its own technical accumulation and practical application results, JiuJu magnetizing equipment has become the preferred product in the industry.

I. High-frequency energy compression technology: the core support of millisecond response

JiuJi equipment adopts capacitor type pulse power supply + multi-stage coil superposition technology to optimize the millisecond response of traditional magnetizers to the 0.1 second level. The core working logic is as follows:

1. Ultra-high-voltage energy storage and instantaneous release: The equipment is built-in imported oil-immersed energy storage capacitor, which can store several megajoules of energy in a single charge/discharge, and with the flat SCR and rectifier module, it can realize the precise delivery of current to the magnetizing coil in the μs-level time.

2. Multi-stage magnetic field superposition design: the outer coil is powered by high-capacity pulsed power supply to provide the basic background magnetic field; the inner coil adopts high power density power supply to superpose the instantaneous peak magnetic field. Through the PLC integrated control system, the two levels of magnetic field operate in concert, so that the total magnetic field strength reaches 10T (Tesla) level within 0.1 second, while the magnetic field uniformity error is controlled within ±0.5%.

II. Magnetic circuit structure and material innovation: core initiatives to reduce energy loss

During the magnetization process, magnetic field leakage and coil overheating are the key problems to be solved. JOJO has optimized this through the following innovative solutions:

1. Split Magnetic Circuit Optimization: Adopting the structure design of "Ring Yoke + Tapered Pole Head", the magnetic field focusing efficiency is improved by 30%, and the magnetic line leakage rate is controlled to below 5%. In the magnetization test of miniature sensors, this design optimizes the rate of change of magnetic field strength gradient on the magnet surface from 12%/mm in conventional equipment to 3%/mm.

2. Nanocrystalline alloy coil skeleton: Fe-Si-B-Nb-Cu nanocrystalline alloy is selected to replace the traditional pure copper wire, its tensile strength can reach 600MPa, and it can still maintain the structural stability under the environment of 10T magnetic field, and at the same time, it can make the coil resistivity decrease by 40%. With the optical isolation pulse control technology, the current attenuation time can be shortened to 1/5 of the traditional solution.

Intelligent Feedback and Process Closure: Technology Upgrade from Magnetization to Magnetization Control

By integrating sensors and AI algorithms, JUJI has upgraded the magnetization process to a dynamically adjustable closed-loop system with the following core advantages:

1. Millisecond Magnetic Field Monitoring: Embedded in the center of the magnetizing coil, the Hall sensor array collects magnetic field strength, direction and distribution data in real time, and the response delay is controlled within 50μs. In the motor rotor magnetization scenario, the system can detect the air gap magnetic field deviation at 0.01mm level and adjust the pulse parameters automatically.

2. Self-optimization of process parameters: Based on historical magnetization data, the system can establish a 3D mapping model of "material - size - magnetic field". For example, for NdFeB N52 magnets, the system can automatically match the 3000V pulse voltage and 200kA peak current to achieve a remanent magnetization Br of 1.48T, which is much more efficient than manual debugging.

The high-frequency magnetic field generator of JUJI pulsed magnetization equipment further expands the efficiency and precision of the magnetization process by virtue of the synergistic innovation of energy compression, magnetic circuit optimization and intelligent feedback. Its 0.1-second magnetization performance not only provides reliable technical support for high-precision manufacturing of motors and sensors, but also shows the broad application potential of strong magnetic field technology in the field of material processing.

Magnetization of Magnetic Materials

3C Electronic Magnetization

Motor Rotor Magnetization

Car Speaker Magnetization

New Energy Vehicle Industry

Medical Equipment Industry

Jiu Ju Magnetizer

Jiu Ju Magnetizer