Can improper wiring of multi-stage magnetizers affect equipment operation? A complete guide to proper operation!

End-to-End Solution for Magnetization Automation

Automated Magnetic Charging Integrated Solution

In industrial production scenarios, JiuJi multi-stage magnetizers are the core equipment for magnetization of all kinds of magnetic materials and play an indispensable role. But do you understand that improper wiring operation may cause equipment failure, abnormal performance and other problems, affecting production efficiency and equipment life? The following is a detailed explanation of its standardized wiring process and operation points.

The effects of improper wiring practices need to be focused on

In the field of motors, if there is a deviation in the winding wiring, such as mistakenly connecting the star method to the triangle method, it will lead to single-phase windings being subjected to excess voltage, which will lead to generator failure due to current overload. Similarly, if the wiring of JiuJi multi-stage magnetizer is not standardized, it will cause the current direction to be inconsistent with the original design of the equipment, and it is easy for the local current to increase abnormally. This can cause damage to core components such as magnetizing coils due to high temperature rise, and may also induce short-circuit problems, leading to abnormal operation or even damage to the equipment, ultimately incurring high maintenance expenses and causing production interruptions.

Specification wiring operation steps in detail

Before operation, the appearance of the equipment should be thoroughly inspected to make sure that the equipment has no signs of damage, the lines are firmly and reliably connected, and the indicators and meters can be normally displayed and function. Especially critical is the need to complete the grounding of the magnetizer according to the norms, which is an important prerequisite to reduce the potential risk of power leakage and to ensure the safety of the operators and the stable operation of the equipment.

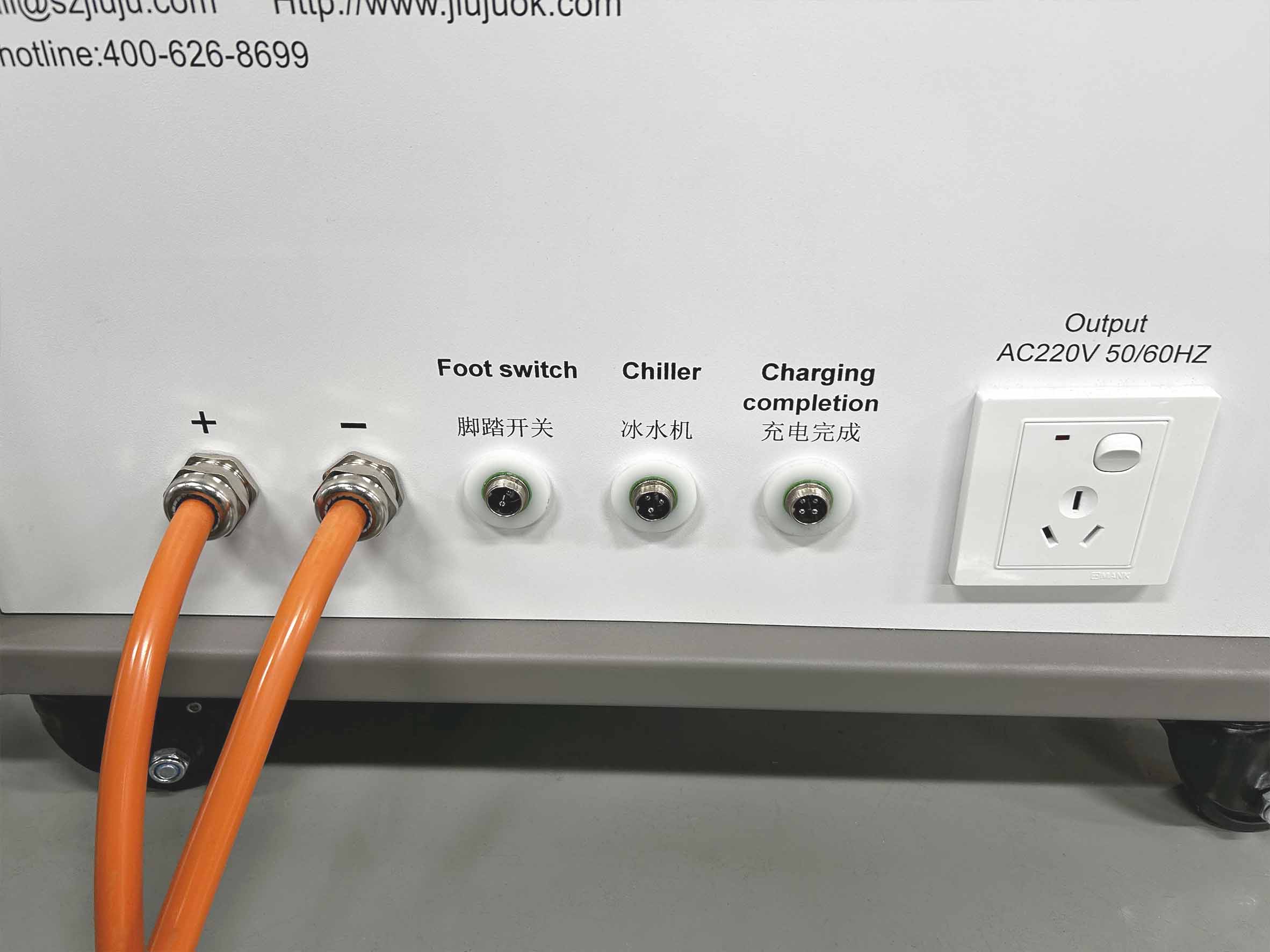

The wiring process should strictly follow the standard procedure of the equipment: the positive pole of the magnetizing coil should be connected correspondingly with the positive pole of the output of the magnetizer (routinely distinguished by a red marking), and the negative pole should be accurately docked with the negative pole of the output of the magnetizer (routinely distinguished by a black marking); the footswitch should be correctly inserted into the "external control socket" designated by the magnetizer, to ensure the normal transmission of signals.

In terms of power supply access, it is necessary to use power cords in accordance with national standards, and the cross-sectional area of the cords should be not less than 6㎜², and the supporting power switch should be a leakage protection switch with a rated current of not less than 63A to ensure the safety of electricity consumption. In addition, JiuJi multi-stage magnetizer adopts two-phase four-wire wiring system, and the specific wiring details can be found in Chapter 5 of the equipment manual for detailed guidelines.

After the wiring is completed, turn on the power supply of the magnetizer, at this time, the power indicator should light up normally, and the voltmeter synchronously displays the input voltage, indicating that the equipment power supply status is normal.

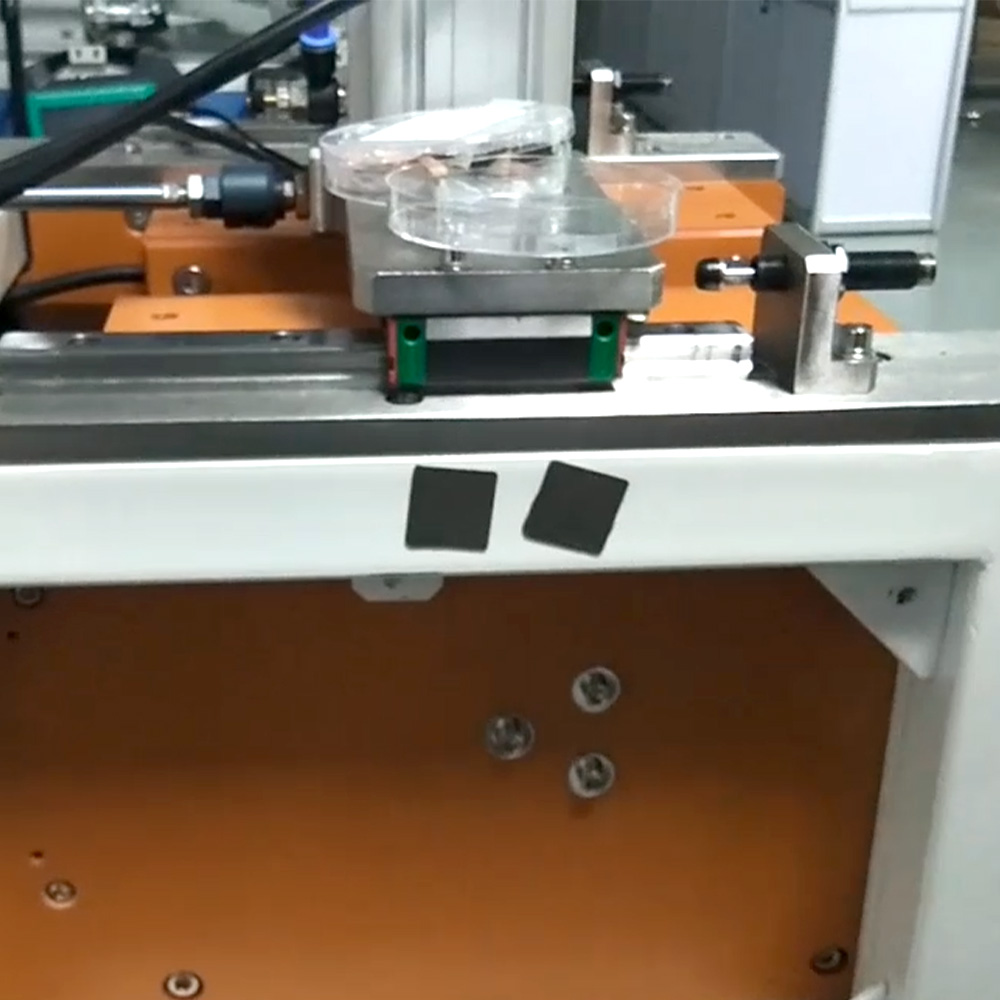

Before placing the workpiece to be magnetized, the appropriate magnetizing coil should be selected in accordance with the material, specification and target magnetic performance requirements of the workpiece, and the capacitance and charging voltage parameters should be reasonably matched. The workpiece should be placed smoothly in the specified precise position of the magnetizing coil to ensure that the workpiece and the coil are tightly fitted and correctly positioned, so as to avoid uneven magnetizing effect due to positional deviation.

Subsequently, key parameters such as charging voltage and magnetizing time are set on the equipment's operating panel according to process requirements. For initial operation, refer to the recommended parameter values in the equipment's manual, and then fine-tune and optimize them according to the actual magnetizing effect.

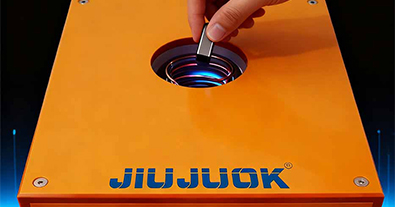

After pressing the "Charge" button, the device will enter the rapid energy storage phase. When the capacitor voltage reaches the preset parameter value, the "Charge Complete" indicator will light up synchronously, at this time, you can press the "Magnetize" button, the device will generate a pulse current flow through the magnetizing coil, forming a strong magnetic field, so as to complete the workpiece magnetization operation.

After the magnetization process, before removing the workpiece, it is recommended to use Gaussmeter and other professional testing equipment to test the magnetic flux of the workpiece to confirm that the magnetic performance indexes are in line with the process requirements.

Magnetization of Magnetic Materials

3C Electronic Magnetization

Motor Rotor Magnetization

Car Speaker Magnetization

New Energy Vehicle Industry

Medical Equipment Industry

Jiu Ju Magnetizer

Jiu Ju Magnetizer