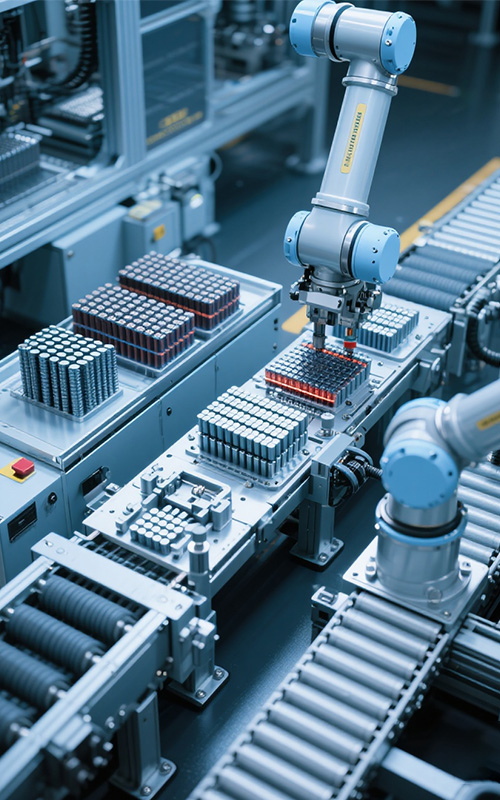

Coil Smart Manufacturing Leads New Journey of Empowering the Industry

Radial Multi-Pole Magnetizing Coil

Radial multipole magnetizing coil

The design of magnetizing head is generally based on the specific requirements of the product, we can design and produce all kinds of internal and external radial multi-pole magnetizing head, plane (end face) multi-pole magnetizing head, shaped face multi-pole magnetizing head, magnetic tile magnetizing device, closed-circuit loudspeaker magnetic circuit magnetizing device and so on. Its function is to convert the electrical energy output from the magnetizer into magnetic field. During the magnetization process, the temperature will directly affect the magnetic saturation.

- Radial Magnetizing CoilsDiameter 10mm-300mm, number of poles 4-128, all can be customized.The following standard specifications are commonly used

| Product Parameters | Model/Specification | ⌀10-⌀50mm | ⌀60-⌀120mm | ⌀140-⌀300mm |

| Number of magnetizing poles | 4-pole, 6-pole, 8-pole, 12-pole, 24-pole, 32-pole, 64-pole, 128-pole | |||

| Product Number | 580400 | 890620 | 148103 | |

| Heat dissipation method | Water-cooled circulation cooling/pure water | |||

| Core depth | Can be customized according to customer requirements | |||

| Insulation material | Polymer epoxy insulated panels, coils cast in epoxy resin | |||

| operating temperature | ≤65 degrees Celsius | |||

| Coil Material | enameled copper wire | |||

| Overall dimensions | Customized size (depending on product size) | Customized size (depending on product size) | Customized size (depending on product size) | |

| weights | Based on actual weight | Based on actual weight | Based on actual weight | |

Product Advantage:

Our radial magnetizing coils can help you improve the efficiency and competitiveness of your magnetic component production, and at the same time meet the trend of precision manufacturing. Whether they are used in micro-motors, sensors, or new energy equipment magnetizing scenarios, they can accurately match the needs and promote the performance upgrade of your products.

- Enhance magnetization efficiency: Adapted to the automated magnetization process, it can quickly complete the synchronous magnetization of multiple poles and efficiently respond to the needs of mass production.

- Guarantee the accuracy of magnetic performance: accurate positioning of magnetic poles, stable output of uniform magnetic field, to ensure the consistency of magnetic parameters of each batch of magnetic components, to improve product quality.

- Reduce the cost of adaptation: support multi-specification magnetic components compatible magnetization, no need to frequently replace the coil, reduce equipment investment and commissioning costs.

- Reinforcement of operational safety: adopting high-temperature-resistant, insulated protective structure, avoiding the safety hazards caused by high pressure and strong magnetism during the process of magnetization, and guaranteeing production safety.

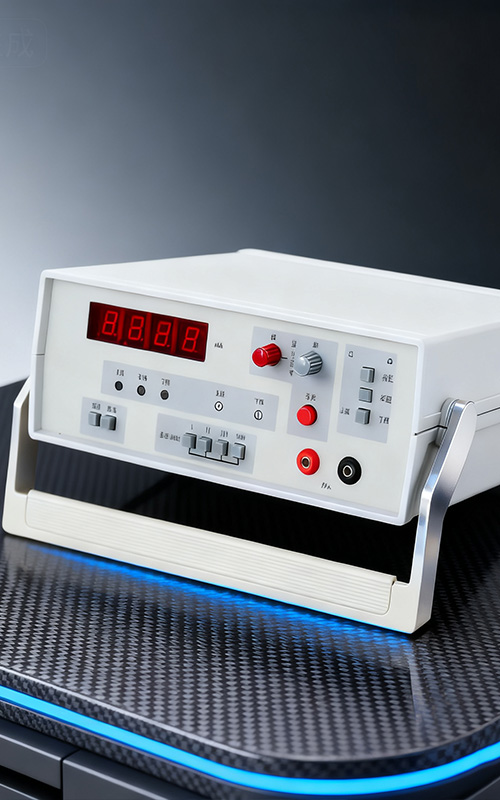

Intelligent Core

Smart Core

Integrating intelligent algorithms and real-time sensing technology, it dynamically adjusts the magnetization parameters (current, phase, magnetic field strength) to achieve accurate modeling and uniformity control of multi-pole magnetic field.

Jiu Ju Magnetizer

Jiu Ju Magnetizer