Smart Automation: Paving the Way to Success

Pioneering Industrial Advancement with Intelligent Solutions

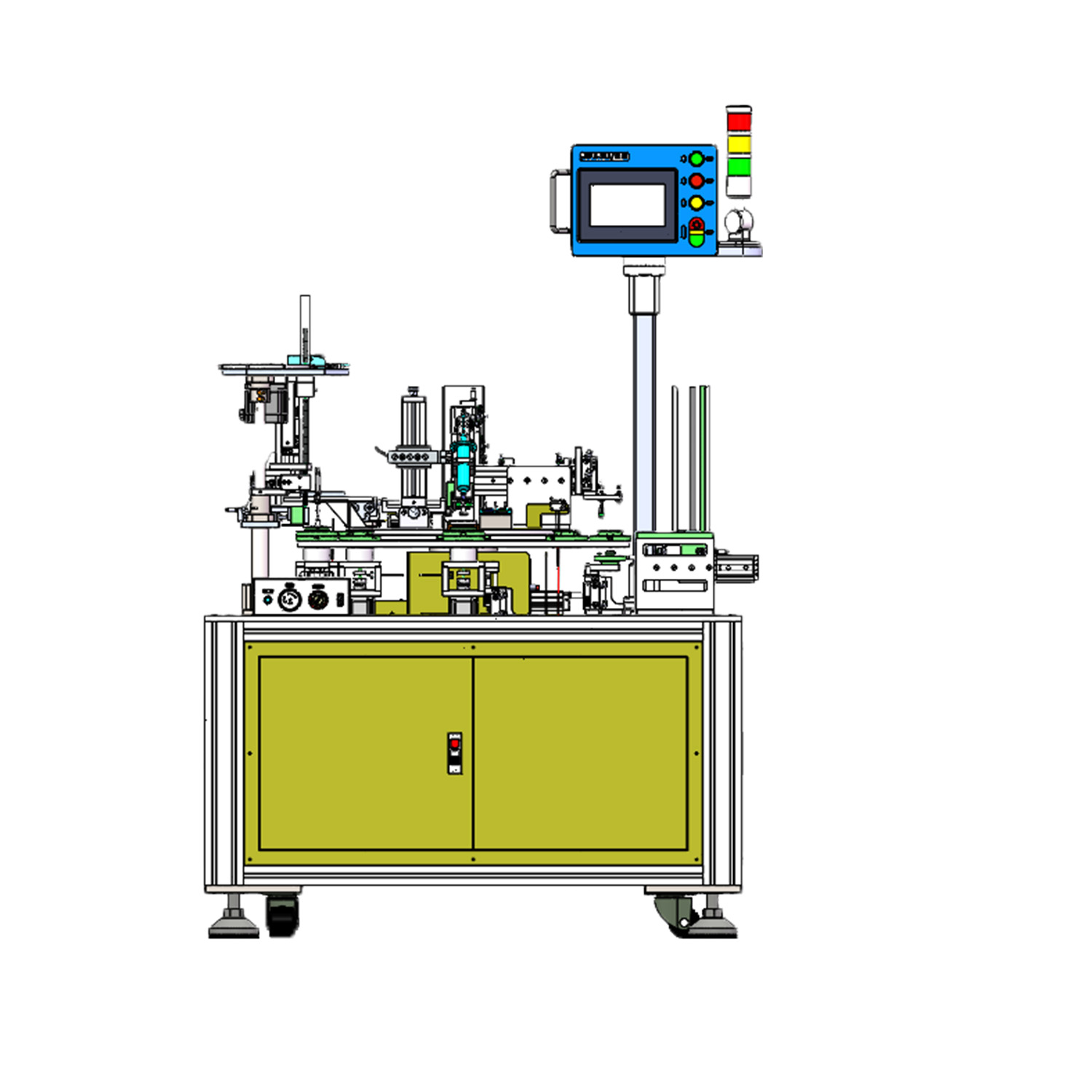

Automatic Wireless Charger Magnet Assembly

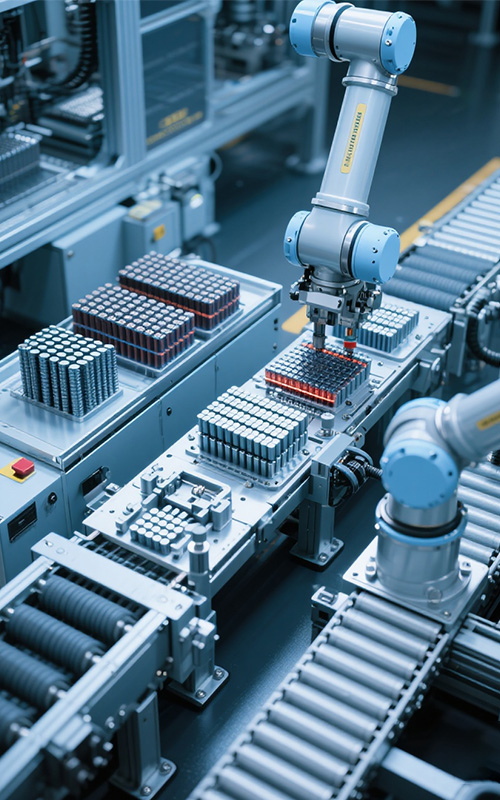

Wireless charging magnet automatic assembly machine is an automated equipment adapted to the production of wireless charging, the core parameters are designed around the assembly efficiency and precision to meet the special needs of magnet assembly.

- Assembly precision: the precision is controlled at the micron level to ensure the accurate alignment of the magnets inside the wireless charger to avoid affecting the charging performance due to deviation.

- Assembly speed: support adjustable speed operation, can match different capacity requirements, from single-station fine assembly to multi-station high-speed assembly flexible switching.

- Adaptation range: compatible with a variety of specifications of wireless charging products, can adapt to different sizes and thicknesses of the magnet, without the need for frequent replacement of the core components.

- Degree of automation: integrated automatic loading, positioning, pressing and testing functions, reducing manual intervention and lowering the risk of error caused by manual operation.

Multi-scenario use

Wireless charging magnet automatic assembly machine can be widely used in consumer electronics, automotive electronics, smart home and other industries, to adapt to different production environments under the wireless charging magnet assembly needs.

It represents the cutting-edge direction of automated production of wireless charging parts, and its core advantage lies in its high degree of adaptability, which is not restricted by specific product models, and can stably perform the task of precise assembly of magnets in all kinds of production lines.

The equipment has a number of key parameters, including assembly accuracy, production speed, compatible magnet specifications, automation integration and safety protection level, supporting its application in multiple fields. It can replace manual labor to complete repetitive assembly work, improve production efficiency and reduce labor costs, while safeguarding the consistency of assembly and quality stability of wireless charging products.

Product Advantage:

Motor automatic magnet insertion steel machine intelligent solution, can help motor manufacturing enterprises to improve production efficiency and core competitiveness, at the same time fit the trend of green and efficient manufacturing, whether it is small home appliance motors, large industrial motors or new energy automobile drive motors magnet insertion scenarios, can accurately meet the needs and promote business upgrading.

- Increase production capacity: Relying on the automated insertion and assembly process and intelligent collaboration of production lines, it significantly improves the magnet assembly efficiency and quickly responds to the market demand for mass production of motors of different specifications.

- Reduce labor costs: Reduce the dependence on manual insertion and assembly, reduce the burden of repetitive labor on employees, and effectively control the enterprise's labor input costs in the motor assembly process.

- Improvement of quality: Equipped with high-precision positioning system and automated insertion and assembly process, avoiding manual operation error, ensuring accurate magnet assembly position and stable performance of each motor, and guaranteeing high product quality.

- Enhance safety: Reduce the direct contact of personnel with precision components and mechanical operation, avoid potential risks such as pinch injuries and misalignment of assembly, and strengthen the safety management of motor production sites.

Jiu Ju Magnetizer

Jiu Ju Magnetizer