Smart Automation: Paving the Way to Success

Pioneering Industrial Advancement with Intelligent Solutions

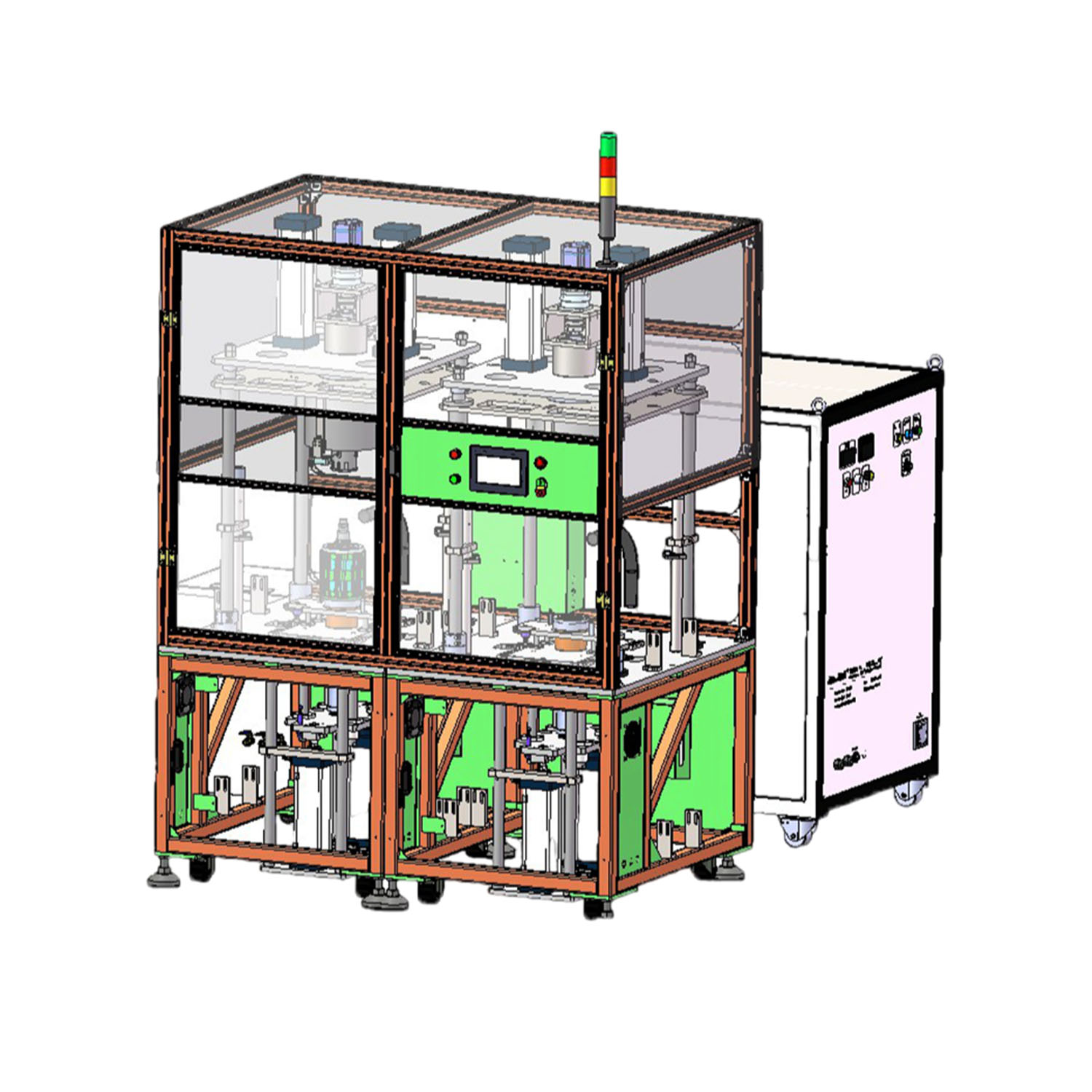

Integrated Magnetizing Equipment

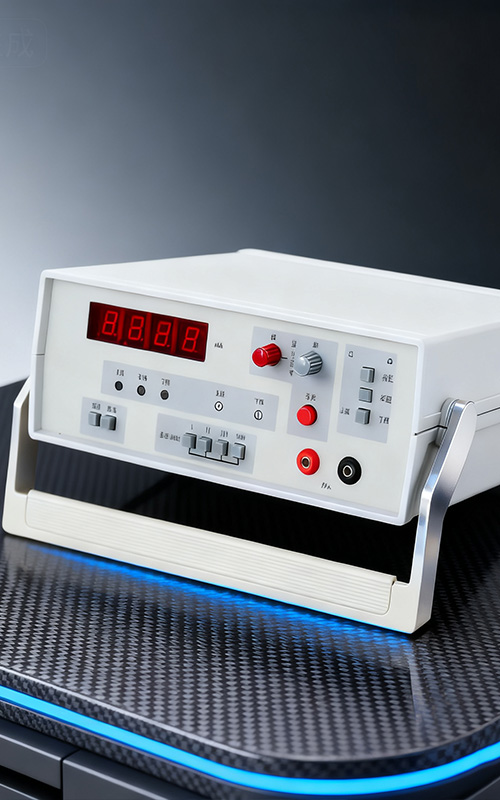

The Integral Magnetizer is a professional magnetic processing equipment with a number of key parameters to meet the magnetization needs of different workpieces.

- Magnetizing Strength: Typically available in different strength levels, from low strength for small precision components to high strength for large industrial parts.

- Workpiece Adaptability: Compatible with a wide range of workpiece sizes and shapes, covering the magnetization needs of miniature parts to large assemblies.

- Magnetization precision: the precision can reach micron level, to ensure that the magnetic field distribution of the workpiece after magnetization is uniform and the parameters reach the standard.

- Processing efficiency: With adjustable magnetization speed, it can be adapted to two scenarios of batch fast processing and high-precision slow magnetization.

- Safety: Built-in magnetic field protection device and intelligent monitoring system can avoid strong magnetic influence on operators and peripheral equipment.

Multi-scenario use

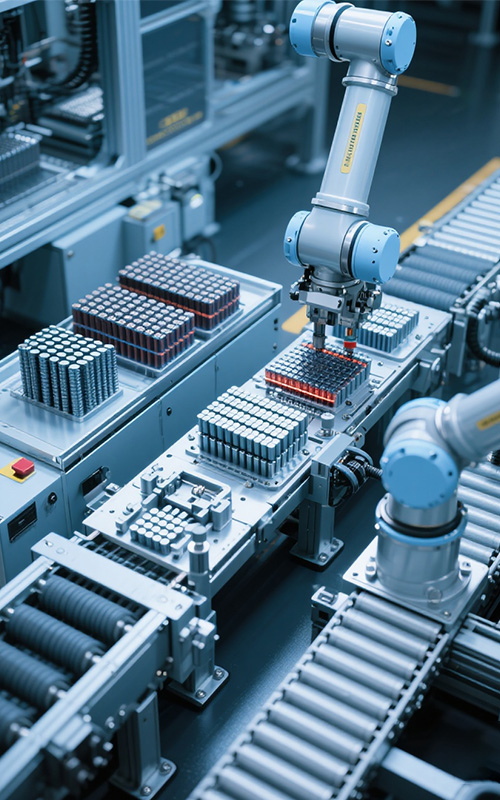

The overall magnetizing equipment has the ability to adapt to multiple scenarios, can be widely used in many industries, compatible with different environments of the workpiece magnetic processing needs.

Integral magnetizers represent a highly efficient solution in the field of magnetic processing. Their core feature is their adaptability to the scenario, regardless of the type of workpiece and industry, and their ability to perform magnetization tasks for different sizes of workpieces in a wide variety of environments.

This type of equipment has key parameters such as magnetizing strength, workpiece adaptation range, magnetizing accuracy, processing efficiency and safety, making it suitable for a wide range of applications. It meets the magnetic processing needs of different industries, improves workpiece magnetization efficiency, reduces manual operation costs, and ensures consistent quality of magnetized workpieces.

Product Advantage:

Our total magnetization equipment can help you improve your productivity and competitiveness, while meeting the trend of green manufacturing. Whether it is used in the magnetization of motors, sensors, or new energy equipment, it can precisely meet the needs and promote the upgrading of your business.

- Improvement of production capacity: Relying on automated operation and intelligent regulation, the efficiency of magnetizing operation is greatly improved, and the market responds quickly to the demand for products with high magnetic properties.

- Reduce labor cost: Reduce the dependence on manual operation, reduce the burden of duplicated labor on employees, and effectively control the cost of human input in enterprises.

- Improvement of quality: Equipped with high-precision testing and automated magnetization process to ensure stable and consistent magnetic properties of each batch of products and guarantee high quality products.

- Enhance safety: Reduce the direct contact of personnel with the magnetization process, avoid potential risks such as high voltage and strong magnetism, and strengthen the safety management of the production site.

Jiu Ju Magnetizer

Jiu Ju Magnetizer